First 3D Printed Superconducting Cavity

First 3D Printed Superconducting Cavity

Materials scientists have studied the mechanical properties of 3D printed materials while ignoring their electrical properties. That looks set to change.

The 3D printing of metal parts promises to revolutionise a wide range of industries. Aircraft carriers, for example, might no longer need to carry spare parts for the myriad aircraft, engines and weapons systems they carry. Instead, each part could be printed as needed.

The big worry of course is that the mechanical properties of 3D printed parts might not match those of parts made in other ways, particularly when they are used as critical components, in high performance jet engines for example.

To that end, materials scientists have spent much time and effort characterising the mechanical properties of these parts. And consequently, they are now used as customized medical implants, jet engine bearings and for rapid prototyping in the car industry.

But while the mechanical properties of 3D printed parts have been well studied, less attention has been paid to their electrical properties.

Today that changes thanks to the work of Daniel Creedon at the University of Melbourne in Australia and a few pals who have designed, printed and successfully tested a superconducting microwave cavity for the first time. They say their work paves the way for a new generation of superconducting components that can be designed and made relatively quickly and cheaply.

Superconducting cavities are the workhorses in an increasing number of experiments to study the properties of the universe. Their purpose is to store microwaves, allowing them to resonate while losing as little energy as possible.

The microwaves interact with the electrons in the surface material of the cavities. So the resistance of this material is an important factor in the performance. Hence the interest in superconducting cavities where the resistance is essentially zero.

Resonating microwaves are useful things—they accelerate charged particles inside particle accelerators, they are ultra-sensitive motion detectors, they can produce highly stable frequencies, help measure the speed of light and so on.

But the cavities that hold them are high precision devices that are time-consuming and expensive to make. 3D printing offers significant advantages in speed and cost, provided the process of printing doesn’t interfere with the cavities’ superconducting properties. That’s something nobody had attempted to measure, until now.

To study the effect of 3D printing on these superconducting properties, Creedon and co simply printed two of cavities using a process which selectively melts aluminium powder so that it solidifies into the required shape. In this way, a complex 3D cavity can be built up layer by layer.

This process is quick and cheap but has several potential limitations. The first is that 3D printing produces shapes with rough surfaces.

The second is that aluminium powder has a different composition to standard industrial aluminium designated Al-6061. In particular, the powder contains some 12 per cent silicon by weight, whereas the usual stuff has only 0.8 per cent. It also contains small amounts of iron (0.118 per cent) and copper (0.003 per cent) compared to 0.7 per cent iron, 0.15 per cent copper and 1.2 per cent magnesium in the industrial stuff.

The impact of these kinds of differences could be important or insignificant but until it is measured, nobody knows which. That’s what Creedon and co set out to do. And to their surprise, they found that neither of these factors has a significant impact on the resulting cavities’ superconductivity.

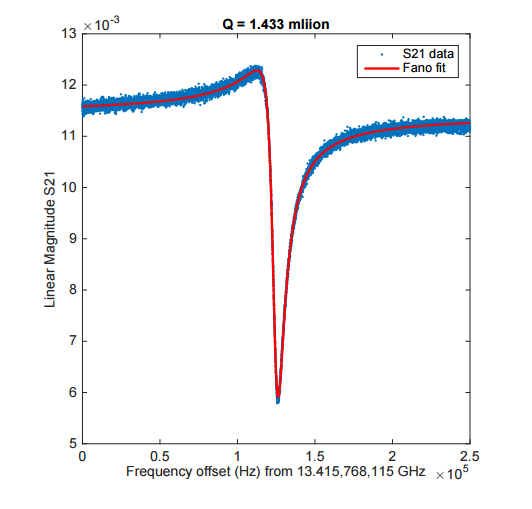

Creedon and co report that the cavities become superconducting at the expected temperature of 1.2 Kelvin and that the electrical properties were similar to those of industrial Al-6061. “The results are comparable to cavities machined from common Al-6061 alloy, and are unaffected by the surface roughness of the cavity walls due to the 3D printing process,” they say.

However, they were able to improve the performance of one cavity by polishing its inside surface to reduce the roughness. They then heated it to 770K for 4 hours and allowed it to cool slowly to room temperature. This has the effect of driving out silicon from the material. “Annealing at 770 K for 4 hours to drive off residual silicon impurities was found to improve the Q-factor by approximately a factor of two,” they say.

That’s interesting work that has further potential. One future avenue would be to use purer aluminium powder. Creedon and co say this should produce higher quality cavities. Another is to start creating cavities that are impossible to manufacture using conventional machining techniques.

A first step on an exciting route to a new era of 3D-printed superconductors.

Ref: arxiv.org/abs/1604.04301 : A 3D Printed Superconducting Aluminium Microwave Cavity

Leave a Reply